Top 5 Centerless Grinding Problems & Grinding Troubleshooting

Table of Contents

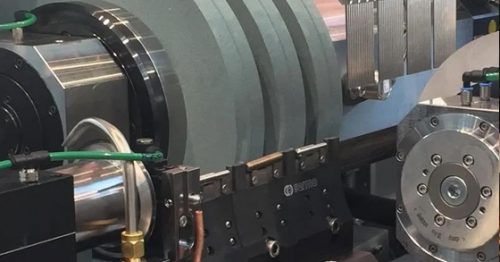

Centerless grinding solves many problems

Centerless grinding is pillar of manufacturing industries around the globe. Centerless grinding earned gratitude because of several pros over other process in industry eg-

- Fast processing ( Time Saving)

- Minimal Load time ( around 3 second per part again time saving)

- Can process multiple diameters and huge number or parts

- Automation is easy in centerless grinders

- Quick to setup for work job

- Tight tolerances

- Longer Life of Grinding wheels

Centerless Grinding Process Errors and solutions

Grinding Related other Resources

- Gear Grinding Process

- Abrasive Material Types

- Abrasive Wheel Types

- A Guide for Rice Mill Machinery

Centerless grinding problems

Regular maintenance of centerless grinding machine can help your business alot and reduces number of problems in grinding process. But when your superstar grinder suddenly becomes non-functional, you’ll start deep diagnosis to find out root cause or problem behind error.

Most of the times, centerless grinders problems are related to grinder’s tooling. So first you should consider grinder’s tooling inspection while starting search for culprit.

Let’s dig deep into the common centerless grinding problems and causes behind problems and hints to solve the grinding problem like a boss.

Also Read : Centerless Grinding Wheel

| Grinding Problem | Troubleshooting |

|---|---|

| Grinder starts making noise | Reduce speed of wheel Reduce stock removal Increase infeed rate Increase traverse feed rate Increase coolant pressure |

| Grinder starts making low sound | Increase speed of grinding wheel Decrease the stock removal Increase dresser’s setting angle Increase Coolant volume |

| Grinding ratio is being decreased | Increase the speed Reduce stock removal Decrease the infeed rate and traverse feed rate Increase dresser’s setting angle Decrease the dressing amount and traverse feed rate |

| Workpiece is burnt | Reduce the amount of stock removed per pass Use a coarser dressing, more ‘open’ Adjust the coolant direction |

| Poor surface finish | Slow down the dresser Inspect, or replace dressing tool Use a softer grade wheel |

Also Read : Centerless Grinding Wheel Suppliers

FAQ about Grinding wheel problems and errors

What to do when Grinding wheel out of balance?

1 First conduct inspection of spindle and collet if burrs present then remove.

2 Check balancing stand level both ways before balancing wheel.

How to fix Loose Wheel Mount?

To fix loose wheel mount of grinder you should Tighten spindle nut or clamping screws through collet.

What are the indications behind Wheel acts too hard?

1 Wheel loading

2 Work discolored

3 Work burned

4 Work Noise

Explore More: Gear Grinding Wheels Manufacturer

Featured Product

Abrasives Surface Grinding Segments

Hindustan surface grinding Segment are a universal choice for all those customers for heavy, rapid stock removal and production work. These Segments can easily handle tolerance operations and are generally preferred in such uses only.

Hai

We are engine valve makers, While during finish center less grinding machine with 20 micron stock removal, All parameter good results,

But we found valve tip end position 3 flat marks cumming, We are looking good solution

Regards

s.soundhar