Common Grinding Problems : Causes and Methods of Correction

In this post, we are going to discuss techniques commonly used to eliminate grinding defects. Common grinding defects such as chatter during grinding and guidelines to establish a problem free foundation for optimizing the grinding process.

Table of Contents

9 most common grinding problems and how to fix them

Grinding is a crucial process in manufacturing and it is important to ensure that it is done accurately and efficiently.

However, there are a number of potential faults that can occur during grinding, such as feed lines or spirals on the workpiece, scratching, burning, and more. In this guide, we will explore the various grinding problems that can occur and provide suggestions for correcting them.

The most frequent problems during grinding include

- Grinding Chatter

- Wheel Loading

- Wheel Glazing

- Burning of Work

- Searching of Work: Indication

- Feed Lines or Spirals on Workpiece

Grinding Chatter

Causes & Method of Correction – Grinding Chatter

- Wheel grading too hard-Use softer grade or coarser grit.

- Wheel out of balance-Rebalance after truing operation. Run wheel without coolant to throw off excess water. When wheel is removed from machine store on side to prevent water from setting at lower edge of wheel.

- Wheel out of round- True before and after balancing.

- Work centers of work rests not true, or improperly lubricated Check fit of centers and rests Provide constant and even lubrication.

Also Read: Pink Aluminum Oxide Grinding Wheel

Wheel Loading – Metal Lodged on Grains or in Wheel Pores

Wheel loading refers to the accumulation of metal particles in the pores of the grinding wheel, which can reduce its cutting performance and cause it to become ineffective.

Causes & Method of Correction

- This can be caused by a variety of factors, including a wheel that is too fine or too hard, poor wheel dressing, or a lack of coolant.

- Incorrect wheel-Use coarser grain size, or more open bond to provide chip clearance.

- Faulty dressing-Use sharper dresser Dress faster

- Coolant-Use more, cleaner and thinner coolant.

- To correct this issue, it may be necessary to use a coarser grit wheel or a softer grade wheel to improve the cutting performance of the wheel. It is also important to carefully dress the wheel using a diamond or other abrasive tool and to ensure that an adequate supply of coolant is being used.

Wheel Glazing (Shiny Appearance)

Wheel glazing refers to the shiny appearance that can occur on the surface of the grinding wheel as it is used.

Causes & Method of Correction

- This can be caused by a variety of factors, including a wheel that is too fine or too finely dressed, poor quality or quantity of coolant, or insufficient wheel breakdown.

- Wheel grading hard and finer grit- Use coarser grain size, softer grade.

- Improper dressing- Keep wheel sharp with sharper dresser. Use faster dressing tool traverse. Use more dressing tool penetration.

- To correct this issue, it may be necessary to use a coarser grit wheel or to give the wheel a more open dressing to improve its cutting performance. It is also important to increase the supply and cleanliness of the coolant and to increase the work and traverse speeds if necessary.

Also Read : White Aluminum Oxide Grinding Wheels Supplier

Burning of Work

Burning of the workpiece can occur when the grinding wheel becomes overheated during the grinding process.

Causes & Method of Correction

- This can be caused by a variety of factors, including a wheel that is too hard, a work speed that is too slow, or poor coolant flow.

- Wheel grading too hard-Use softer grade. Prevent glazing and loading. Use more coolant.

- Faulty operation-Bring wheel to work more gradually, use less in-feed. Prevent stoppage of work while in contact with wheel.

- To correct this issue, it may be necessary to use a softer grade wheel or to increase the work speed to improve the cooling of the wheel. It is also important to ensure that the coolant is directed at the grinding contact point and to increase the supply of coolant if necessary.

Searching of Work – Indication

Causes & Method of Correction

- Wavy traverse line-Cause-ragged wheel Use round of wheel edges

- Isolated deep marks-Causes

- Improper wheel dressing-Use sharper dressing tools. Brush wheel after dressing.

- Coarse grains or foreign material in wheel face. Dress it out.

- Deep irregular marks-Cause-Loose wheel flanges Tighten flanges using blotters.

- Grain marks-Causes

- Wheel too coarse or too soft- Use finer grain size of harder grade wheel.

- Too much difference in grain size between roughing and finishing wheels. – Use finer roughing wheel or finish out better with roughing wheel.

- Dressing too coarse- Less dresser penetration and slower traverses.4

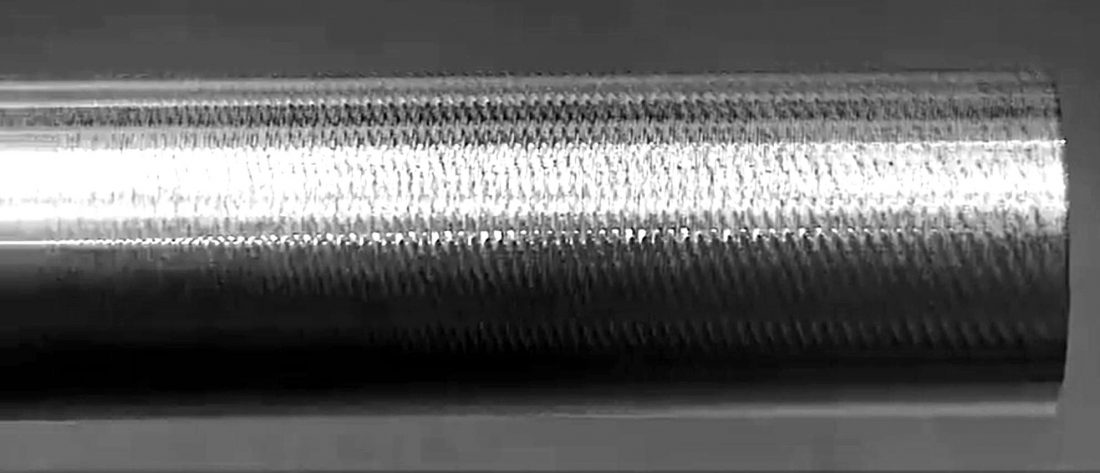

Feed Lines or Spirals on Workpiece

Feed lines or spirals on the workpiece are marks that are left behind by the grinding wheel as it moves across the surface of the workpiece.

Causes & Method of Correction

- These marks can be caused by a variety of factors, including poor wheel dressing, a wheel that is too hard or too soft, or faulty wheel dressing.

- To correct this issue, it is important to carefully redress the wheel using a diamond or other abrasive tool to reshape the surface and remove any imperfections.

- Additionally, using a softer grade wheel or reducing the feed rate of the wheel may help to prevent it from cutting too aggressively. It is also important to ensure that the wheel head is properly aligned and not causing the wheel to make improper cuts.

Scratching of Work

Scratching on the workpiece can be caused by a variety of factors, including a wheel that is too hard or too coarse, dirty coolant, or a wheel infeed that is too fast

Causes & Method of Correction

- To correct this issue, it may be necessary to use a softer grade wheel or a finer grit wheel to improve the cutting performance of the wheel.

- It is also important to ensure that the coolant is clean and flowing properly, and to reduce the wheel infeed rate if necessary.

Bell-Mouthed Hole

A bell-mouthed hole refers to a hole that has a wider opening at one end than at the other.

Causes & Method of Correction

- This can be caused by a variety of factors, including a wheel that is too soft, uneven travel past each end of the hole, or tipped workhead.

- To correct this issue, it may be necessary to use a harder grade wheel or to adjust the overtravel to be equal on both ends. It is also important to realign the workhead and to carefully “zero” the centers to ensure that the hole is being ground evenly.

Out-of-Round Hole Became Distorted

An out-of-round hole that becomes distorted can be caused by a variety of factors, including a wheel that is too hard, spindle material that is not rigid enough, or a defective belt.

Causes & Method of Correction

- To correct this issue, it may be necessary to use a softer grade wheel or to replace the spindle or belt if necessary.

- It is also important to balance and/or true the wheel and to avoid using bushed wheels, as these can cause additional vibration and contribute to distortion.

Grinding problems can be frustrating, but with the right knowledge and tools, they can be corrected. By following the suggestions outlined in this guide, you can improve the precision and quality of your grinding process.

We also encourage you to consider Hindustan Abrasives as your go-to supplier for high-quality grinding wheels.

With years of experience and a commitment to producing top-notch products, Hindustan Abrasives is a trusted choice for all of your grinding needs.

Explore: Grinding wheel manufacturers

Featured Product

Abrasives Surface Grinding Segments

Hindustan surface grinding Segment are a universal choice for all those customers for heavy, rapid stock removal and production work. These Segments can easily handle tolerance operations and are generally preferred in such uses only.