Guide to Improve Grinding Profitability as Production Manager / Engineer

You can improve your grinding profitability by tracking and measuring following parameters. These parameters all work together and adjusting one or more parameters changes the result.

Balancing important parameters allows you to improve grinding efficiency by making necessary changes.

Let’s discuss with important main factors that influence grinding efficiency.

Table of Contents

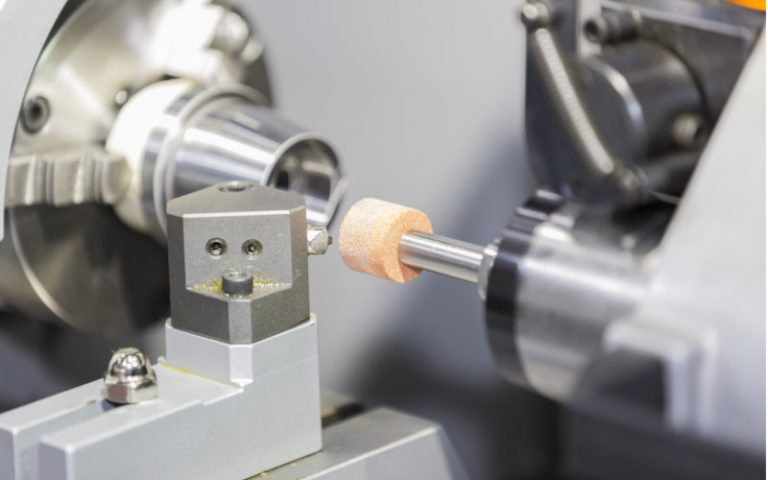

1) Machine and tools

Rigidity, precision and dynamic stability-if everything of this factor is not working together in harmony, then your work piece won’t be consistent in quality.

2) Other Machine Tool

Other factors include power and speed availability control capability, slide movement, truing and dressing mechanism-each of these factors control the accuracy of where the grinding wheel and work piece positioned during a job.

3) Cooling system

It controls the temperature, provides lubrication and removes small chips during grinding.

Ensuring each of this factor is properly addressed and maintained helps to grinding machine run at peak efficiency

Also Read : Grinding Machine Safety Precautions

4) Wheel selection factor

The abrasive, grit size, grade and bond type should be correctly selected to fit the particular job.

Also the size and shape should match the geometry of work piece.

For more details about wheel selection factors, read our : Grinding wheel selection Guide

5) Operational factor

The productivity accuracy and cost of grinding processes depend to a considerable extent on correct choice of process parameters, as the advantage of good machine and correct wheel can be lost by operating them under unfavorable conditions.

Also Read: Pink Aluminum Oxide Grinding Wheel

However it is important to understand the operational factors, including wheel balancing fixturing, frequency of truing and dressing and coolant application. Knowing how these factors , and others interact with each other is secret to understanding what happening in the grinding zone.

To discover how to optimize the grinding processes need to focus on few specific factors from each of the all above parameters and measuring how results change. It provides specific accurate information, and is much better than taking shotgun approach and changing a handful of factors at once.

Looking at the all above parameters, there are two keys achieving results with minimal variations: establishing standard practices to ensure consistency and using reliable equipment to measure precision. Usually, you’ll measure acceptable consistency by using SPC, or statistical process control.

Also Read: Handling and Storage Method of Abrasives Grinding Wheels

Reduce Economic Costs

Now let’s discuss how to reduce economic costs.

Measuring factors that affect profitability and efficiency, such as cost/part, production rate and the finished product performance are vital pcs to the economic part.

Once you collect economic related data, it is time to compare with all factors. Combines reliable process control with the system approach with skilled operator to discover the needed adjustments for improved results.

Their experience and wide range of knowledge allow them to apply fundamental principles with variables and parameters that are specific to your company to find out how to optimize grinding process for increased productivity.

Featured Product

Abrasives Surface Grinding Segments

Hindustan surface grinding Segment are a universal choice for all those customers for heavy, rapid stock removal and production work. These Segments can easily handle tolerance operations and are generally preferred in such uses only.