Handling and Storage Method of Abrasives Grinding Wheels

Handling of Grinding Wheels

All the abrasive wheels are breakable and some are very fragile. Great care shall be exercised in handling and storage to prevent damage which might cause a wheel to fly apart when speed up.

- Wheel shall be handled carefully to prevent dropping or bumping.

- Wheels shall not be rolled except in exceptional circumstances in which case a soft resilient floor surface is essential.

- Suitable conveying devices shall be employed for transportation of wheels which can not be carried by hand.

- Wheels shall be carefully stacked in trucks, trolleys or other conveying machinery. Heavy material or tools shall not be placed over the wheels. Stacking shall be such as not to allow toppling over of wheels.

Also Read : Guide to Improve Grinding Profitability

Storage of Grinding Wheels

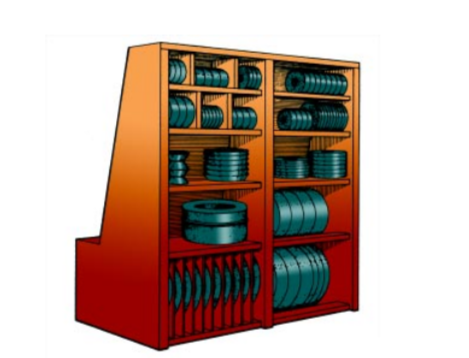

Suitable racks, bins or drawers shall be provided to accommodate various types of wheels used, and shall have ample strength to carry the imposed loads. Most plain and taper sided wheels can be stacked on edge in racks.

Such racks as far as practicable, should provide two point cradle support for the wheels to prevent rolling.

Grinding wheels must be protected while awaiting use. Wheel storage should be arranged to allow wheel selection and removal without disturbing and damaging other wheels.

Also Read : Aluminum Oxide Grinding Wheels

Such suitable storage shall be available for partly used wheels as well as new wheels.

Storage and records should also be set up to allow for wheel use on rotational basis so that wheels will be in storage a minimum length of time. This minimises the possibility of damage from lengthy storage.

Also Read : Grinding Machine Safety Precautions

Featured Product

Abrasives Surface Grinding Segments

Hindustan surface grinding Segment are a universal choice for all those customers for heavy, rapid stock removal and production work. These Segments can easily handle tolerance operations and are generally preferred in such uses only.