Truing a Grinding Wheel: Guide to Achieving Optimal Grinding Performance

Table of Contents

Truing a Grinding Wheel

Truing a grinding wheel refers to the process of reshaping the abrasive surface of the wheel to restore its geometric accuracy and remove any irregularities or damages. This process is crucial for maintaining optimal grinding performance in various machining operations. A grinding wheel that is properly trued ensures precise and consistent results, improves surface finish, reduces vibration, and prolongs the life of the wheel.

Importance of Truing for Optimal Grinding Performance

Truing a grinding wheel is of paramount importance to achieve optimal grinding performance. A poorly trued wheel can lead to various issues such as uneven material removal, poor surface finish, increased grinding forces, and excessive heat generation. These problems not only affect the quality of the machined parts but also pose risks to the safety of operators and equipment.

Truing a grinding wheel provides several benefits. First, it restores the wheel’s concentricity, ensuring uniform contact between the wheel and the workpiece. This results in improved accuracy and surface finish. Second, truing removes any irregularities or damages on the wheel’s surface, preventing chatter marks and reducing vibration during grinding. Third, truing helps maintain the desired wheel profile, which is essential for specific grinding applications.

Checkout our Products Catalogue

Properly trued wheels also reduce the likelihood of wheel loading, a common issue where grinding debris accumulates on the wheel surface, diminishing its cutting ability. By truing the wheel, the exposed fresh abrasive grains are utilized effectively, ensuring efficient material removal rates.

In summary, truing a grinding wheel is vital for achieving optimal grinding performance, ensuring precision, surface finish, and extending the wheel’s lifespan. The following sections will delve into the different methods and steps involved in truing a grinding wheel.

Understanding Grinding Wheel Truing

Definition of Truing a Grinding Wheel

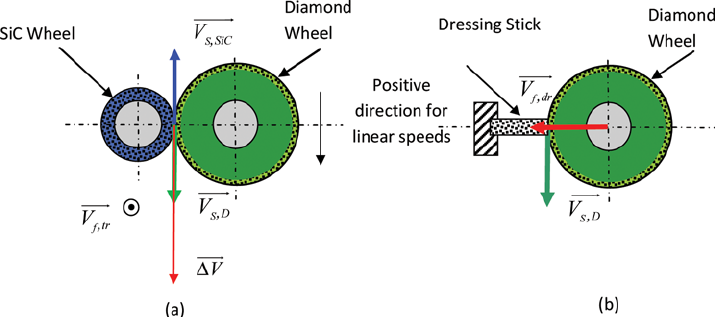

Truing a grinding wheel involves reshaping its abrasive surface to restore its geometric accuracy. This process removes any irregularities or damages that may have occurred during grinding operations. Truing is distinct from dressing, which involves removing dull grains and exposing fresh abrasive grains on the wheel’s surface.

Truing corrects the shape and alignment of the wheel, ensuring it runs true and maintains the desired profile during grinding operations. It is an essential step to optimize grinding performance and achieve precise results.

Difference between Truing and Dressing a Grinding Wheel

While truing and dressing are related processes, they serve different purposes. Truing focuses on restoring the wheel’s geometry, while dressing is aimed at maintaining the wheel’s cutting ability.

Truing involves reshaping the wheel to eliminate any irregularities, such as out-of-roundness or misalignment. It ensures that the wheel runs true and maintains the desired profile during grinding. Truing corrects the form of the wheel.

On the other hand, dressing removes worn-out or dull grains from the wheel’s surface, exposing fresh abrasive grains. This process helps to maintain the wheel’s cutting ability by preventing it from becoming glazed or clogged with grinding debris. Dressing involves the use of special tools or devices, such as diamond dressers or dressing sticks, to remove the unwanted material from the wheel.

Both truing and dressing are essential for maintaining a grinding wheel’s performance, but they serve different purposes in the overall grinding process.

Why Truing is Necessary for Grinding Operations

Truing is necessary for grinding operations to achieve accurate and consistent results. When a grinding wheel is not properly trued, it can lead to several problems:

- Inaccurate Workpiece Dimensions: A poorly trued wheel can result in dimensional inaccuracies in the workpiece. Irregularities in the wheel’s shape or alignment can cause uneven material removal, leading to variations in the workpiece dimensions.

- Poor Surface Finish: If the wheel is not properly trued, it can produce a poor surface finish on the machined part. Irregularities on the wheel’s surface can cause chatter marks, surface roughness, or waviness, negatively affecting the part’s aesthetics and functionality.

- Increased Grinding Forces: A wheel that is not properly trued may generate higher grinding forces during the machining process. This can lead to excessive heat generation, increased power consumption, and accelerated wear of the wheel.

- Vibration and Chatter: Improperly trued wheels can cause vibration and chatter during grinding. This not only affects the quality of the machined surface but also impacts the stability of the grinding machine and the safety of operators.

By truing the grinding wheel, these problems can be mitigated. Truing restores the wheel’s geometric accuracy, ensuring proper contact between the wheel and the workpiece, consistent material removal, improved surface finish, and reduced vibration.

Factors Affecting the Need for Truing

The need for truing a grinding wheel can be influenced by several factors. Understanding these factors helps in determining the frequency and extent of truing required. Some of the key factors include:

- Wheel Wear: As the grinding wheel is used, the abrasive grains gradually wear down, reducing the wheel’s diameter and changing its shape. Increased wheel wear necessitates more frequent truing to maintain the desired profile and cutting performance.

- Grinding Forces: High grinding forces, such as those encountered in heavy-duty grinding operations or when machining hard materials, can cause greater wheel wear and deformation. Consequently, more frequent truing may be necessary to restore the wheel’s shape.

- Wheel Hardness: The hardness of the grinding wheel affects its wear resistance and tendency to deform. Softer wheels may require more frequent truing compared to harder wheels.

- Wheel Material: Different wheel materials have varying properties, such as hardness, toughness, and friability. These properties affect the wheel’s performance and wear characteristics, influencing the truing requirements.

- Grinding Parameters: Factors such as the grinding speed, feed rate, depth of cut, and coolant usage can influence the wear and behavior of the grinding wheel. Aggressive grinding conditions may necessitate more frequent truing.

- Machine Rigidity: The rigidity and stability of the grinding machine play a significant role in maintaining the accuracy of the grinding wheel. Machines with inadequate rigidity can lead to wheel deformation and the need for more frequent truing.

By considering these factors, operators and technicians can determine the optimal truing frequency and method to ensure consistent and reliable grinding performance.

Types of Grinding Wheel Truing Methods

Manual Truing Methods

- Hand-held Diamond Dressers Hand-held diamond dressers are portable devices used for truing grinding wheels manually. They consist of a handle and a diamond-tipped point. The diamond point is applied to the rotating wheel’s surface to remove material and reshape the wheel. Hand-held diamond dressers are suitable for smaller wheels or when a quick touch-up is required during the grinding process.

- Single-point Diamond Dressers Single-point diamond dressers feature a single diamond point mounted on a handle or shank. The diamond point is positioned against the rotating wheel’s surface, creating a truing action. This method is commonly used for precision truing of larger grinding wheels. The single-point diamond dresser provides more control and precision compared to hand-held dressers.

- Brake-controlled Truing Devices Brake-controlled truing devices are mechanical devices that employ a braking mechanism to control the truing process. These devices feature a diamond or abrasive wheel, which is brought into contact with the grinding wheel to reshape it. The brake-controlled truing method offers increased control and stability during truing operations, ensuring accurate wheel geometry.

Mechanical Truing Methods

- Stationary Truing Devices Stationary truing devices are mounted fixtures that hold the grinding wheel in a fixed position during the truing process. These devices can incorporate different truing mechanisms, such as diamond tools, abrasive wheels, or grinding stones. The grinding machine’s spindle or a separate truing attachment is used to drive the truing device. Stationary truing devices are often used for larger wheels or when precise truing is required.

- Rotary Truing Devices Rotary truing devices are mounted on the grinding machine’s spindle and rotate at high speeds. These devices feature a diamond or abrasive wheel that is brought into contact with the stationary grinding wheel to reshape it. The rotation of the truing device ensures even and consistent truing action across the entire wheel surface.

- Truing Machines Truing machines are specialized equipment designed specifically for truing grinding wheels. These machines offer automated truing processes and are capable of handling various wheel sizes and types. Truing machines can incorporate different truing methods, such as diamond tools, grinding stones, or rotary truing devices. They provide precise control over truing parameters, ensuring consistent and accurate results.

Truing with Specialized Tools

- Profiling Tools Profiling tools are designed to create specific wheel profiles for specialized grinding applications. These tools consist of a shaped form or template that is pressed against the rotating wheel’s surface, transferring the desired profile onto the wheel. Profiling tools are commonly used for complex wheel geometries or when precise profiles are required.

- Abrasive Sticks or Stones Abrasive sticks or stones can be used for truing grinding wheels, especially when minor adjustments or touch-ups are needed. These sticks or stones are made of abrasive materials and are manually applied to the rotating wheel’s surface. They can remove material and reshape the wheel to some extent.

- Truing Templates Truing templates are precision-made templates or guides that provide the desired wheel profile. They are positioned against the rotating grinding wheel, and the shape of the template is transferred onto the wheel’s surface, reshaping it accordingly. Truing templates are particularly useful for achieving complex wheel profiles and ensuring consistent truing results.

Each truing method offers advantages and suitability for specific grinding applications. The choice of truing method depends on factors such as wheel size, complexity of the required profile, precision requirements, and available equipment.

Steps to Truing a Grinding Wheel

1- Preparation

- Ensuring Safety Measures Before initiating the truing process, it is crucial to adhere to safety protocols. Operators should wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and protective clothing. The grinding machine should be turned off, and its power supply should be disconnected to prevent accidental activation during truing.

- Gathering Necessary Tools and Equipment Identify and gather the required truing tools and equipment based on the selected truing method. This may include diamond dressers, truing devices, abrasive sticks or stones, and other accessories specific to the chosen method.

- Securing the Grinding Machine Ensure that the grinding machine is properly secured to prevent movement or vibration during the truing process. Stabilizing the machine enhances truing accuracy and safety.

2- Inspection

- Checking the Condition of the Grinding Wheel Carefully examine the grinding wheel for any signs of damage, wear, or irregularities. Inspect the wheel for cracks, chips, glazing, or excessive wear. Identifying any issues beforehand helps determine the extent of truing required.

- Identifying Irregularities and Damages If there are irregularities or damages present on the wheel’s surface, make note of their location and extent. This information will guide the truing process and help focus on specific areas that require correction.

3- Selecting the Truing Method

- Choosing the Appropriate Truing Method for the Grinding Wheel Type Consider the characteristics of the grinding wheel, such as its material, size, and profile requirements, when selecting the truing method. Different methods are better suited for specific wheel types and truing objectives. Refer to manufacturer recommendations or expert advice if necessary.

- Considering the Required Truing Precision Evaluate the desired truing precision based on the application requirements. Some truing methods offer higher levels of accuracy and control, while others are suitable for less precise truing needs. Assess the importance of achieving the desired profile and dimensional accuracy.

Executing the Truing Process

- Setting up the Truing Device or Tool Prepare the selected truing device or tool according to the manufacturer’s instructions. Mount the truing device securely or hold the tool firmly in hand, ensuring stability during the truing process.

- Applying the Truing Process to the Grinding Wheel Initiate the truing process by bringing the truing device or tool into contact with the rotating grinding wheel. Follow the recommended technique for the selected method, whether it involves moving the truing device along the wheel’s surface, pressing the tool against the wheel, or using rotational motion.

- Ensuring Proper Control and Precision Maintain control and precision throughout the truing process. Apply consistent pressure, maintain a steady speed, and closely monitor the truing action. Adjust the truing parameters, such as the contact angle, feed rate, or tool position, as necessary to achieve the desired truing results.

- Removing Excessive Material and Reshaping the Wheel Profile Continue the truing process until the desired profile is achieved or the necessary corrections are made. Remove any excess material or irregularities on the wheel’s surface, ensuring a smooth and even profile.

Evaluation and Adjustment

- Inspecting the Trued Grinding Wheel for Desired Profile After completing the truing process, inspect the grinding wheel to evaluate the achieved profile. Compare it to the desired profile or specifications. Assess the wheel’s surface for uniformity, smoothness, and absence of irregularities.

- Making Necessary Adjustments for Optimal Performance If the trued wheel does not meet the desired profile or performance requirements, additional adjustments may be necessary. This can involve repeating the truing process, modifying truing parameters, or considering alternative truing methods. Fine-tuning the trued wheel ensures optimal grinding performance.

Troubleshooting and Common Challenges

Common Issues During the Truing Process

Even with proper techniques and precautions, truing a grinding wheel can encounter some challenges. It is important to be aware of these common issues to address them effectively. Some of the common issues include:

- Wheel Loading: Wheel loading occurs when grinding debris or swarf builds up on the wheel’s surface, reducing its cutting ability and causing poor grinding performance. Wheel loading can occur during truing due to the presence of excessive bonding material or swarf. This issue may require additional cleaning or use of specialized cleaning sticks to remove the built-up debris.

- Inaccurate Truing: Inaccurate truing can result from improper truing techniques, incorrect truing parameters, or inadequate control during the process. It can lead to a misshapen wheel or an incorrect wheel profile. To address this issue, review and adjust the truing technique, parameters, or equipment setup as necessary.

- Excessive Wheel Wear: Excessive wheel wear during truing may indicate the use of incorrect truing methods or inadequate truing control. Excessive wear can reduce the wheel’s lifespan and result in more frequent truing requirements. To minimize excessive wear, evaluate the truing technique, ensure proper control, and consider alternative truing methods if necessary.

Troubleshooting Tips and Solutions

- Addressing Wheel Loading Issues To mitigate wheel loading, ensure effective chip evacuation during grinding operations. Use appropriate coolant or lubrication to minimize swarf buildup. During truing, periodically clean the wheel’s surface using specialized cleaning sticks or tools to remove any accumulated debris.

- Correcting Inaccurate Truing To address inaccurate truing, review and refine the truing technique and parameters. Pay attention to maintaining consistent contact, pressure, and speed during truing. Check for any misalignments or defects in the truing device or tool. Calibrate or replace the truing equipment if necessary.

- Managing Excessive Wheel Wear To manage excessive wheel wear during truing, assess the truing method and parameters. Adjust the feed rate, contact pressure, or tool condition to minimize wear. Consider alternative truing methods that offer better control and minimize wheel wear. Regularly monitor and measure the wheel’s wear rate to ensure timely truing.

By identifying and troubleshooting these common issues, operators can overcome challenges and ensure effective truing for optimal grinding performance.

Best Practices for Grinding Wheel Truing

A. Regular Truing Schedule Implement a regular truing schedule based on factors such as wheel wear, grinding frequency, and the specific application requirements. Regular truing prevents the wheel from losing its shape, maintains the desired profile, and maximizes grinding performance.

B. Proper Maintenance of Truing Tools and Devices Regularly inspect and maintain truing tools and devices to ensure their proper functioning. Clean diamond dressers, check for wear or damage, and replace them as necessary. For mechanical truing devices, ensure proper lubrication and calibration to maintain accuracy.

C. Using Appropriate Truing Techniques for Different Wheel Materials Different grinding wheel materials require specific truing techniques. Softer wheels may require less aggressive truing, while harder wheels may need more force or specialized truing methods. Understand the characteristics of the wheel material and select the appropriate truing technique accordingly.

D. Ensuring Safety Precautions During the Truing Process Safety should be a top priority during the truing process. Adhere to safety guidelines, use appropriate PPE, and ensure the grinding machine is properly secured and disconnected from power. Avoid placing hands or body parts near rotating wheels during truing.

E. Training and Skill Development for Operators Providing training and skill development opportunities for operators involved in truing operations is essential. Proper training ensures operators understand the truing process, techniques, and safety precautions. Skilled operators can perform effective truing, resulting in improved grinding performance and increased productivity.

By following these best practices, operators can optimize the truing process, maintain the wheel’s performance, and achieve consistent and reliable grinding results.

Truing a grinding wheel is critical for maintaining optimal grinding performance in various machining operations. It ensures accurate dimensions, improves surface finish, reduces vibration, and enhances safety. Proper truing extends the life of the grinding wheel and results in high-quality machined parts.

The process of truing a grinding wheel involves several steps, including preparation, inspection, selecting the truing method, executing the truing process, and evaluating the results. Following best practices such as regular truing schedules, proper maintenance of truing tools, using appropriate truing techniques, ensuring safety precautions, and providing operator training contribute to successful truing and optimal grinding performance.

Final Thoughts on Achieving Optimal Grinding Performance through Truing Truing a grinding wheel is a crucial aspect of achieving optimal grinding performance. It requires careful attention to detail, proper selection of truing methods, and adherence to best practices. By understanding the importance of truing, applying the appropriate truing techniques, and maintaining a regular truing schedule, operators can ensure consistent and accurate results, enhancing overall grinding performance and productivity.