Grinding Burn : Causes, Detection, and Prevention for Preserving Precision”

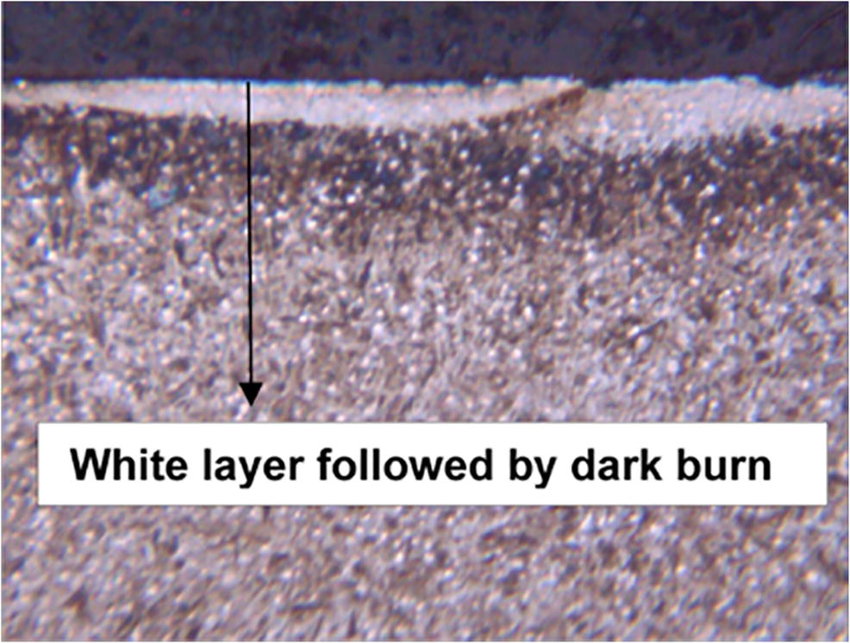

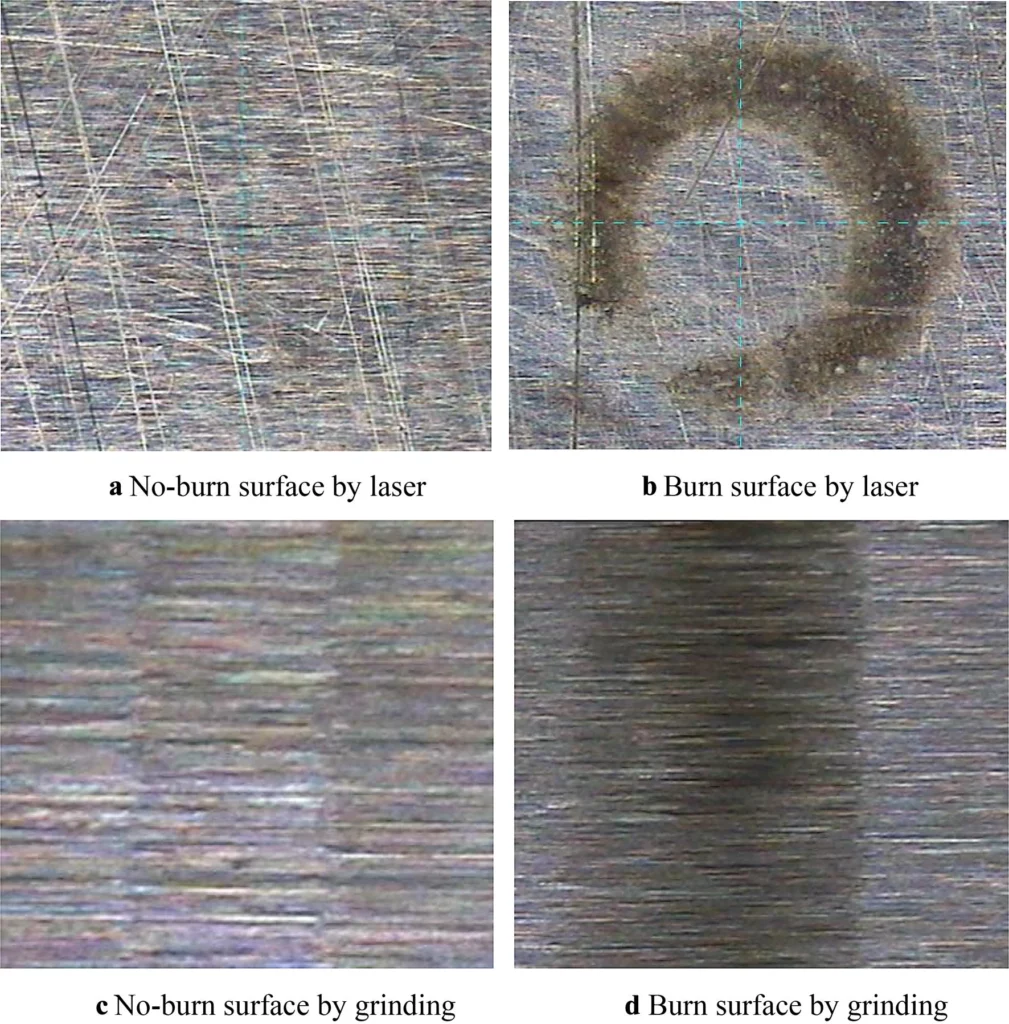

“Grinding burn is a form of thermal damage that affects ground components due to improper grinding procedures. It arises when the energy generated during grinding generates excessive heat. The material undergoes rapid cooling, resembling a tempering process in effect.

Grinding burn can result in several detrimental outcomes, including reduced hardness, heightened tensile residual stress, diminished fatigue resistance, and surface rehardening. Detecting grinding burn is achievable through the application of magnetic Barkhausen noise analysis.

Additionally, it’s worth noting that a shallow grit-penetration depth can exacerbate this issue, as it causes the abrasive grits to lose their sharpness more quickly.”

Table of Contents

Grinding Burn : Why You should Prevent it During Grinding Process?

Grinding is a vital process in the manufacturing industry, used to achieve precise dimensions and a smooth surface finish on various workpieces. However, in the pursuit of perfection, there’s a hidden threat known as “Grinding Burn.” This thermal damage can compromise the quality of your workpiece and lead to a range of issues. In this article, we will delve deep into the world of grinding burn, exploring its causes, detection methods, and how to prevent it.

Defining Grinding Burn

Grinding burn is a thermal damage that occurs during the grinding process due to excessive heat generation. This heat can cause significant changes to the material properties, affecting its integrity and performance.

Consequences of Grinding Burn

When grinding burn occurs, several adverse effects manifest, including decreased hardness, increased tensile residual stress, reduced fatigue resistance, and even surface rehardening. These consequences can compromise the quality and durability of the workpiece.

Causes of Grinding Burn

Factors Leading to Thermal Damage

Grinding burn is a result of various factors, including incorrect grinding parameters, inadequate coolant flow, and the choice of grinding wheel. Understanding these factors is crucial in preventing grinding burn.

The Role of Energy Dissipation

The energy generated during grinding can be likened to a double-edged sword. While it is essential for material removal, excessive energy can lead to heat buildup, causing grinding burn. Finding the right balance is key.

Detection of Grinding Burn

Magnetic Barkhausen Noise Analysis

This non-destructive testing method has emerged as a valuable tool for detecting grinding burn. It involves analyzing the magnetic properties of the workpiece to identify areas affected by thermal damage.

Non-destructive vs. Destructive Testing

We explore the different approaches to testing for grinding burn, weighing the benefits and drawbacks of each method.

Preventing Grinding Burn

Factors to Consider During Grinding

Manufacturers can take proactive steps to prevent grinding burn. This section discusses the importance of selecting appropriate grinding parameters, ensuring effective coolant flow, and monitoring wheel conditions.

Coolant Flow and Work Speed

We delve into how coolant flow and work speed play crucial roles in maintaining the temperature during grinding, thus preventing thermal damage.

Wheel Infeed and Grit-Penetration Depth

Shallow grit-penetration depth can exacerbate the problem as grits become dull. Discover how to manage this aspect effectively.

Real-world Applications and Case Studies

Research and Industry Insights

In the realm of manufacturing and precision engineering, understanding the practical implications of grinding burn is of paramount importance. This knowledge isn’t confined to theoretical discussions; it is validated and enriched through real-world applications and case studies. These case studies offer invaluable insights into the impact of grinding burn on mechanical properties and the significance of quality control measures.

To navigate the complex landscape of grinding burn, it’s essential to stay abreast of the latest developments and research in the field. Industry experts and researchers continually explore innovative techniques for detecting and preventing grinding burn. These insights are the building blocks of progress in ensuring the integrity and reliability of finished products.

Real-world Case Studies:

Real-world case studies serve as windows into practical scenarios where grinding burn can have substantial consequences. These studies often involve actual components or workpieces that have undergone grinding processes. They shed light on the challenges faced by manufacturers and the strategies employed to mitigate grinding burn.

For instance, a case study might showcase how a manufacturer in the aerospace industry detected and rectified grinding burn on critical engine components. Such insights provide a tangible understanding of the issues at hand and the solutions employed to maintain quality standards.

Impact on Mechanical Properties:

One crucial aspect of these case studies is their focus on the impact of grinding burn on the mechanical properties of materials. Engineers and quality control experts analyze the changes in hardness, residual stress, and fatigue resistance resulting from grinding burn. This information is vital for optimizing processes and materials to prevent these detrimental effects.

The Significance of Quality Control:

Through these case studies, the role of quality control in averting grinding burn becomes evident. Quality control measures are explored, emphasizing their role in identifying and rectifying issues early in the manufacturing process. This proactive approach not only saves costs but also ensures the reliability and safety of the end products.

In summary, real-world applications and case studies are invaluable tools for deepening our understanding of grinding burn. They bridge the gap between theory and practice, offering practical insights that can drive improvements in manufacturing processes and product quality.

Credits:

Header Image source : https://www.researchgate.net/figure/Example-of-grinding-burns-in-AISI-52100-steel-15_fig6_342152756