OD Grinding & ID Grinding Fundamentals

Precision grinding of the outer surface of any cylindrical piece is called OD grinding. OD grinding operations on cylindrical pieces, are done on two different types machines. Centre or centerless type, and by two different methods of applying the work pieces to the grinding wheel. The difference in two methods is based in the method of feeding the jobs into the machine.

Read about : Grinding Wheel Specifications

Table of Contents

Centre Type Cylindrical Grinding

When the OD grinding occurs on the external surface of a workpiece between the centres is called center type cylindrical grinding. The centres are the end point that hold the workpiece at the geometric true centre, move it in a rotational direction, allow the grinding operation.

The work piece rotates around that true centre axis. At the same time, the grinding wheel is also rotated and when the two surfaces make contact, they are then moving in opposite directions.

This allows for smooth grinding while reducing the chance of the wheel and work jamming up. Movements in centre type cylindrical grinding-Traverse: Traverse is the movement of work across the wheel parallel to axle of work. The speed of movement of wheel across the work is called rate of traverse.

Infeed: Infeed is the movement of grinding wheel face in a plane perpendicular to and into the surface of job being ground. The amount of feed determines the depth of penetration of the abrasive grain into the work and depth of cut.

Read about : What is Grinding Process and Its Applications

Centre Less Type Cylindrical Grinding

When the cylindrical work piece is not supported on fixed centres but by a combination of a) work piece rest blade b) regulating wheel c) and the grinding wheel itself is called centerless grinding. Movements in centerless grinding: Traverse: In centerless type through feed cylindrical grinding traverse is the movement of work parallel to the axis of the grinding wheel and work (supported by the work rest table) between the regulating wheel and grinding wheel.

Infeed: In centerless grinding infeed is movement of the work piece into the wheel face perpendicular to the axis of grinding wheel.

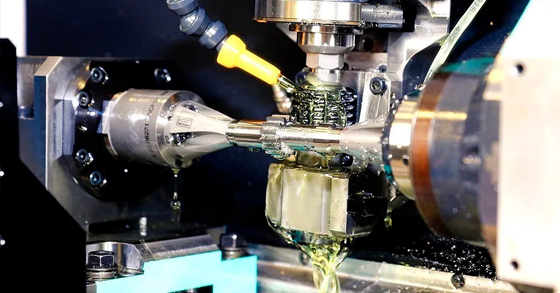

ID Grinding

Precision grinding of the inside surface of the hole in a work piece is called ID grinding. Followings are the three main internal grinding methods.

a) Traverse Grinding

In traverse grinding, the wheel spindle reciprocates over the length of the bore, the component being held on its outer diameter.

b) Plunge Grinding

In plunge grinding, the component is held on the outside but the position of wheel is set to the part of component to be ground. It is fed into the component by the movement of the wheel head, at the right angles to the axis of the component.

c) Grinding the end of blind holes

This is carried out by using a recessed wheel or straight cup wheel.

Precision Grinding Wheels

Featured Product

Abrasives Surface Grinding Segments

Hindustan surface grinding Segment are a universal choice for all those customers for heavy, rapid stock removal and production work. These Segments can easily handle tolerance operations and are generally preferred in such uses only.